Cable Solutions for Wind Energy & Turbines

Solutions for Extreme Operating Conditions

For guaranteed safe cabling of your wind turbines, HEW-KABEL is by your side! Quickly and accurately - our full-service custom solutions have been developed specifically for the extreme operating conditions of wind-based power generation.

With more than 50 years of experience, we offer reliable and durable cabling solutions for various wind power applications, such as:

- Electric power generators

- Rotor de-icing systems

- Rotor braking systems

- Temperature monitoring

- Lightning protection

- Emergency shutdown

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/6/csm_HEW_Wind_Broschuere_7c391bad82.jpg)

1.4 MB

Our Products and Services Include ...

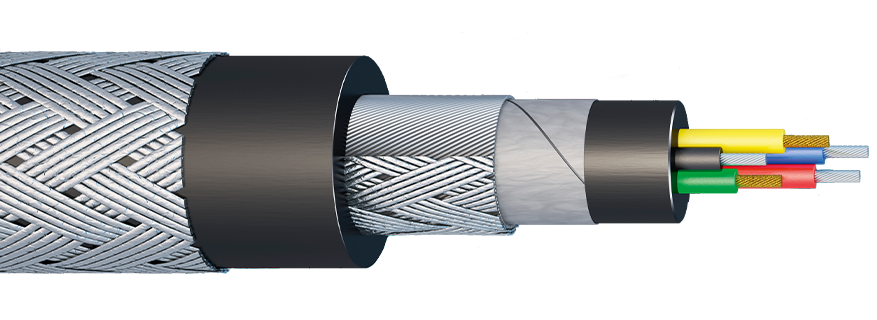

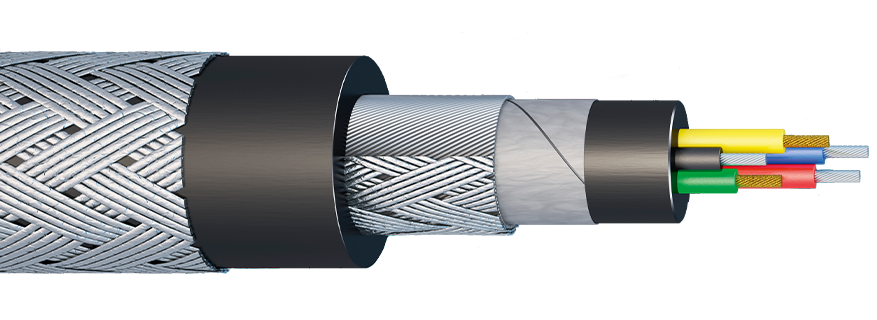

Data Cables

- Shielded cables

- Bus cables

- Sensor cables

- Drive control

Control Lines

- Control of actuators (motors)

- Signal transmission of the fire alarm system

- Signal transmission of the slip ring

Servo Lines / Power Lines

- Power supply of the actuators

- Transmission of power currents

Hybrid Lines

- Combination of different applications in a single line (e.g. control and power line)

Customized Cables According to Individual Customer Requirements

We offer customized special cables in quantities as low as 110 yards.

Designed for maximum performance that meets your every need.

Cables from HEW-KABEL are resistant to:

- Wear

- Bending

- Torsion

- Notch

- Temperature

- Oil and chemical

- UV and ozone

- Tested and certified

Cable structure, material selection and manufacturing processes are determined on an individual basis to ensure that the cable matches your requirements exactly.

Our cabling solutions are extremely versatile, exceptionally temperature resistant and highly mechanically resilient. This enables us to actively minimize service costs over the entire service life of your wind turbine.

| HEW silicone/polyester conductor SIFGA-Cu vz (4 - 185) mm² 13.8 kV | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cross section | 4 | 6 | 10 | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 | 185 |

| Environmental temperature | Permissible continuous current (A) | |||||||||||

| 40°C | 69 | 89 | 121 | 162 | 214 | 262 | 327 | 402 | 485 | 560 | 642 | 730 |

| 80°C | 58 | 74 | 102 | 137 | 180 | 222 | 276 | 340 | 410 | 473 | 542 | 617 |

| 120°C | 45 | 58 | 79 | 106 | 139 | 171 | 214 | 263 | 317 | 366 | 420 | 477 |

| 150°C | 31 | 41 | 55 | 61 | 81 | 99 | 123 | 152 | 183 | 211 | 297 | 338 |

HEW CABLE SOLUTIONS in Windenergy

Please click on the plus icons on the image for more information.

Exemplary Special Cables for Your Application in the Wind Energy Sector

Do you need sample layouts and further technical information regarding our special cables? Download our brochure "HEW - Wind" here for more information on generators, lightning protection, or rotor blade heating.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/6/csm_HEW_Wind_Broschuere_7c391bad82.jpg)

1.4 MB

Examples of Our Cable Solutions

| HEW Silicone/Polyester Adreleitung | |||||

|---|---|---|---|---|---|

| Structure | SIFGA- Cu vz 95 mm² 1,1kV | ||||

| Outer diameter | (18.6 ± 0.9 mm) | ||||

| Temperature range | -50°C to +180°C | ||||

| Bending radius | fixed installation: 4 x D | ||||

| Permissible continuous current | Environmental temperature | 30°C | 60°C | 90°C | 120°C |

| Ampere | 594 | 538 | 472 | 391 | |

| HEW Silikon/Polyester Adreleitung | |||||

|---|---|---|---|---|---|

| Structure | SIFGA- Cu vz 185 mm² 1,1kV | ||||

| Outer diameter | (24.5 ± 1.2 mm) | ||||

| Temperature range | -50°C to +180°C | ||||

| Bending radius | fixed installation: 4 x D | ||||

| Permissible continuous current | Environmental temperature | 30°C | 60°C | 90°C | 120°C |

| Ampere | 890 | 806 | 708 | 587 | |

| HEW EPR/TPE-U core cable | ||

|---|---|---|

| Structure | RY- Cu blk 50 mm² (392x0,0404mm) 600V | |

| Outer diameter | (15.4 ± 0.5 mm) | |

| Bending radius | fixed installation 7.5 x D | free movement 16 x D |

| HEW silicone/polyester core cable | |||

|---|---|---|---|

| Structure | SIFGA- Cu vz 240 mm² (1221x0,5mm) 3,3 kV | ||

| Outer diameter | (28.4 ± 0.4 mm) | ||

| Temperature range | fixed installation -55°C to 180°C | free movement -50°C to +180°C | |

| Bending radius | 7.5 x D | 15 x D | |

| Permissible continuous current | Environmental temperature | 20°C | 90°C |

| Ampere | 950 | 720 | |

| HEW PTFE heating cable | ||

|---|---|---|

| Structure | TE-WM 1.000 Ohm/km (7x0,30 mm) 300/500V | |

| Outer diameter | (28.4 ± 0.4 mm) | |

| Temperature range | -190°C to +260°C | |

| Bending radius | fixed installation 7.5 x D | free movement 15 x D |

New at HEW-KABEL

robotic solutions

HEW develops and manufactures special cables for the application in wind turbines. These cables are assembled by our subsidiary robotic solutions from a single source - whether prototypes or series production. For these purposes, we offer a broad portfolio of ready-to-use solutions including:

Cable protection sleeves

- Predestined for heavy duty applications

- High abrasion resistance, highest flexibility

- For applications ranging from -58°F to + 302°F

Pre-assembled cables

- Primary cables

- Bus cables

- Motor cables

- Servo cables

![[Translate to English:] Robotic Solutions Windkraft](/fileadmin/user_upload/02_Anwendungen-und-Loesungen/05_Windkraft/Robotic-Solutions-Wind_700x455.jpg)

The Perfect Cable for You!

Whether single or multi-core, shielded or unshielded, these cables with material combinations of fluoropolymers, thermoplastics, silicone, or special materials enable customized solutions for safe and secure connections in wind turbines.

Please get in touch with us. We will find the perfect solution!